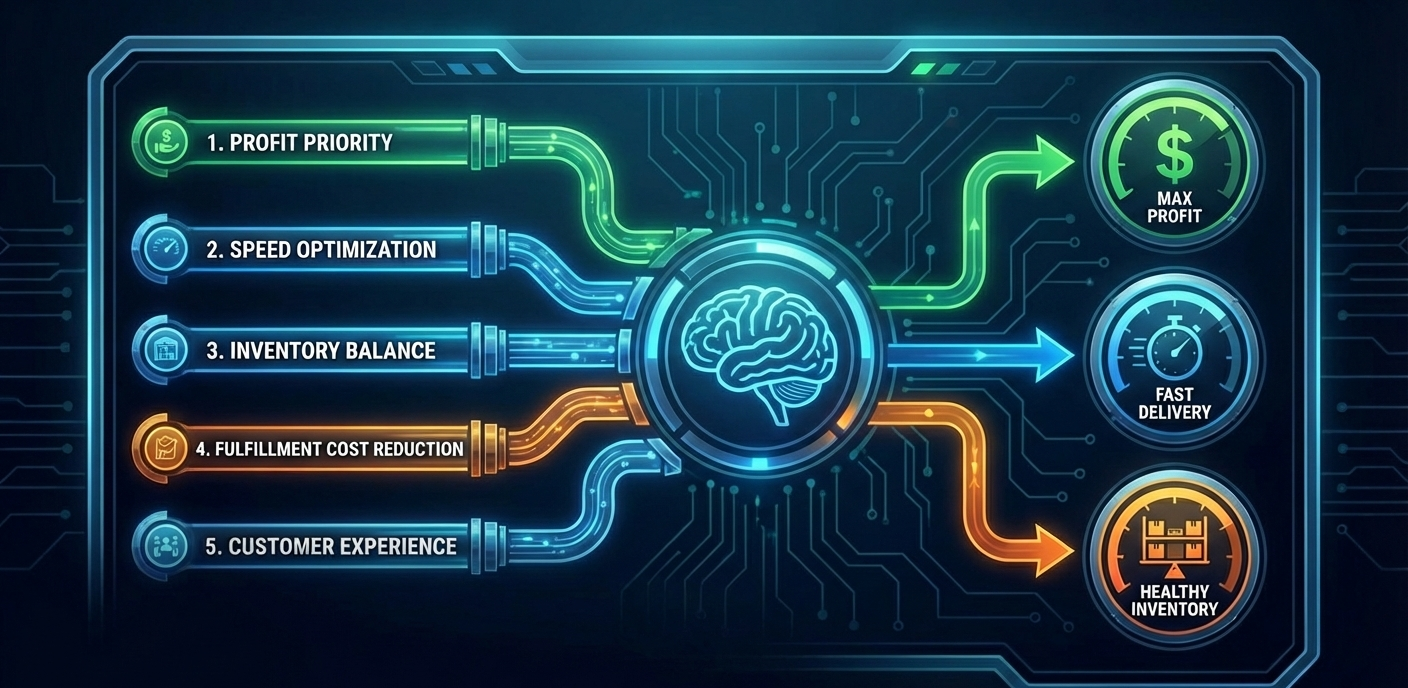

Ecommerce brands are increasingly managing inventory across multiple warehouses, retail stores, and third-party logistics partners. In such a complex environment, every fulfillment decision affects profit, delivery speed, and inventory health. This is where smart order routing becomes essential. Instead of simply shipping from the closest location, modern routing logic evaluates inventory levels, operational capacity, shipping costs, and service-level commitments. By following 5 logic rules to prioritize profit, speed, and inventory health, brands can optimize their fulfillment network, reduce costs, and improve customer satisfaction. This blog breaks down these rules and shows how they create a resilient, efficient, and profitable ecommerce operation.

Why Smart Order Routing Matters in Multi-Location Fulfillment

Most brands still rely on simple routing logic, such as shipping from the closest location to the customer. While this may reduce transit time, it often ignores inventory availability, shipping cost, and operational efficiency. In a multi-location setup, every fulfillment decision affects margin and customer experience.

Smart order routing allows systems to evaluate multiple factors at once, including stock levels, location capability, shipping cost, and service level commitments. Instead of treating fulfillment as a basic distance problem, it treats it as a business decision.

When routing logic is configured correctly, brands gain better control over inventory flow, reduce waste, and improve delivery performance across channels.

Rule 1: Minimize Split Shipments to Protect Profit

One of the most expensive mistakes in fulfillment is splitting a single customer order across multiple locations. Each split shipment requires additional packaging, labels, and carrier charges.

When one location can fulfill the entire order, routing logic should favor consolidation, even if another location is geographically closer. Shipping one box from a single location is almost always cheaper than shipping two boxes from different locations.

This rule helps reduce logistics costs, simplifies operations, and protects margins. Over time, minimizing split shipments leads to significant savings, especially for multi-item orders.

Rule 2: Prioritize Aging Inventory to Improve Inventory Health

Dead stock is a silent problem for many retailers. Inventory that sits too long in stores or warehouses eventually requires markdowns or write-offs.

Smart order routing can help solve this by prioritizing locations with older inventory. Instead of always shipping from the central warehouse, the system should route orders to locations where inventory has been sitting longer.

This approach improves inventory turnover, frees up shelf space, and converts slow-moving stock into revenue without discounting. It is especially valuable in categories like fashion, electronics, and footwear, where product life cycles are short.

Rule 3: Use Hyper-Local Routing for Speed-Sensitive Orders

Speed is a competitive advantage, especially for next-day or same-day delivery promises. For these orders, routing decisions must be precise.

Hyper-local routing uses pin-code or zip-code level mapping instead of broad regional rules. This ensures orders are assigned to locations that can realistically meet delivery time commitments.

When configured correctly, this rule allows brands to use local courier partners, reduce last-mile costs, and meet strict delivery expectations. It is essential for quick commerce and premium delivery offerings.

Rule 4: Protect Marketplace SLAs with Channel Prioritization

Not all orders carry the same risk. Marketplace orders often have strict dispatch deadlines and penalties for non-compliance. Website orders usually allow more flexibility.

Routing logic should recognize this difference. High-priority channels must be protected with reserved inventory or preferred fulfillment locations. This prevents situations where lower-priority orders consume stock needed to meet marketplace commitments.

Channel-based routing safeguards seller ratings, avoids penalties, and ensures compliance with service level agreements. It also creates clarity when demand spikes across multiple channels at once.

Rule 5: Reduce Compliance Complexity with Intra-Region Fulfillment

Tax and regulatory requirements vary by region. Shipping across regions often involves additional documentation, tax handling, and administrative effort.

Smart routing logic should first look for inventory within the same tax jurisdiction as the customer. This reduces compliance overhead, speeds up dispatch, and lowers the risk of errors.

In regions with complex tax structures, such as India or the EU, intra-region fulfillment simplifies operations and improves overall efficiency.

How These Rules Work Together in a Real System

Each of these rules is powerful on its own, but the real value comes from stacking them correctly. Smart order routing systems evaluate multiple conditions in sequence, applying priorities and fallbacks when needed.

A strong setup also includes safeguards such as capacity limits for stores, safety stock thresholds to protect walk-in customers, and fallback rules when no location meets the ideal criteria.

This layered logic transforms routing from a static rule set into a dynamic decision engine that adapts to real-world conditions.

The Role of Technology in Smart Order Routing

Executing these rules consistently requires a capable order management platform. The system must be able to ingest inventory data, understand location capabilities, and apply logic in real time.

This is where a robust OMS becomes critical. It acts as the brain of fulfillment, coordinating inventory, orders, and routing decisions across the network. Smart order routing is a key component of effective Sales Order Management, ensuring that every order is fulfilled in the most efficient way possible.

Why Smart Order Routing Improves Long-Term Performance

Brands that invest in smart routing see improvements beyond short-term cost savings. Inventory moves faster, fulfillment teams work more efficiently, and customer satisfaction improves.

More importantly, the fulfillment network becomes resilient. As stores open, close, or change formats, routing logic can adapt without disrupting operations. This flexibility is essential in a fast-changing retail environment.

FAQs

What is smart order routing?

Smart order routing is a system-driven process that determines the best location to fulfill an order, considering inventory, delivery speed, shipping costs, and operational constraints.

How can these 5 rules improve ecommerce profitability?

By minimizing split shipments, moving aging stock, speeding delivery, prioritizing channels, and optimizing compliance, brands reduce costs, increase inventory turnover, and protect margins.

Is smart order routing necessary for omnichannel retail?

Yes. Brands selling across multiple channels, warehouses, and stores need smart routing to manage complexity and maintain consistent customer experience.

How does smart order routing affect inventory health?

It ensures older stock is sold first, prevents dead stock accumulation, and improves overall inventory turnover across the network.

Final Thoughts

Smart order routing is not just a logistics feature. It is a strategic capability that directly impacts profit, speed, and inventory health. By minimizing split shipments, clearing aging stock, enabling fast local delivery, protecting marketplace commitments, and simplifying compliance, brands can build a fulfillment network that works smarter, not harder. When these five logic rules are implemented together, they create a strong foundation for scalable and profitable ecommerce operations. In a competitive market, the right routing decision can be the difference between growth and inefficiency.