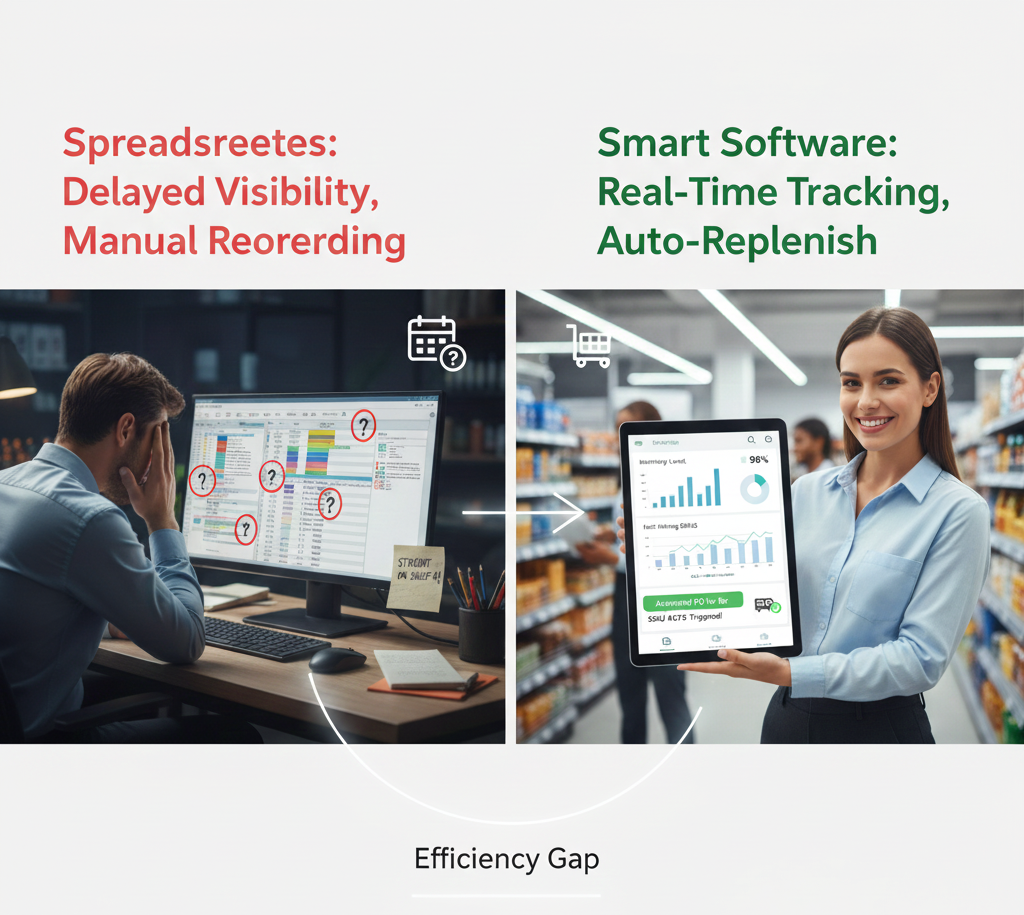

Spreadsheets are no longer enough to manage retail inventory. What once worked for basic stock tracking now creates blind spots, delays, and costly errors. Retailers still relying on spreadsheets are losing real-time inventory visibility, accurate demand forecasting, operational efficiency, and revenue from frequent stockouts or overstocking.

Unlike spreadsheets, modern stock management software automates inventory tracking, synchronizes data across stores and warehouses, and enables smarter, faster replenishment decisions. The result is better control over inventory, fewer losses, and stronger customer satisfaction. As retail operations become more complex, the gap between manual tools and intelligent stock systems continues to grow.

Why Retailers Still Use Spreadsheets for Inventory

Many retailers continue using spreadsheets for inventory management because they feel familiar, affordable, and easy to control. Spreadsheets have a low initial cost, allow quick customization, and don’t require formal training to get started. For small teams, they often seem like the simplest way to track stock manually.

However, this approach is no longer sustainable in 2026. As product catalogs grow, sales channels expand, and customer expectations rise, spreadsheets fail to provide real-time visibility, automation, and forecasting. What worked for basic tracking now creates inefficiencies, errors, and costly inventory gaps that slow down modern retail operations.

Key Limitations of Spreadsheets

1. No Real-Time Inventory Visibility: Spreadsheets rely on manual data entry, which means stock numbers are always delayed. By the time updates are made, actual inventory levels may have already changed due to sales, returns, or transfers. This creates blind spots where retailers make decisions based on outdated information, leading to stockouts or excess inventory.

2. High Risk of Manual Errors: Spreadsheets are highly error-prone. A single wrong formula, accidental overwrite, or duplicate file version can distort stock data. As teams grow, different versions of the same sheet often circulate, making it difficult to trust which numbers are accurate and increasing the risk of costly inventory mistakes.

3. No Automated Replenishment: Spreadsheets cannot trigger actions automatically. Every reorder depends on someone manually checking stock levels and creating purchase orders. This reactive approach slows down replenishment and increases the chances of missing fast-moving products, especially during peak demand periods.

4. Poor Multi-Location Control: Managing inventory across multiple stores, warehouses, or online channels is extremely difficult with spreadsheets. There is no centralized system to sync stock in real time, making it hard to track transfers, prevent overselling, and balance inventory across different locations.

Spreadsheets vs Stock Management Software

| Feature | Spreadsheets | Stock Management Software |

| Real-time stock updates | No | Yes |

| Automated replenishment | No | Yes |

| Demand forecasting | Basic / Manual | Predictive |

| Multi-store management | Difficult | Built-in |

| Error risk | High | Low |

Spreadsheets rely on manual inputs and delayed updates, while stock management software provides real-time inventory tracking, automated stock replenishment, predictive demand forecasting, and seamless multi-location control with significantly lower risk of human errors.

How Stock Management Software Solves These Problems

Modern stock management platforms replace slow, manual spreadsheet workflows with automation, real-time visibility, and data-driven planning. Here’s how they eliminate the biggest inventory challenges retailers face:

1. Real-Time Inventory Tracking

Spreadsheets rely on manual updates, which means your stock data is always playing catch-up.

Stock management software gives retailers live, accurate inventory visibility across every store, warehouse, and sales channel.

With real-time tracking, teams can instantly see:

• What’s selling fast

• What’s about to run out

• What’s stuck as slow-moving inventory

• Stock positions across all locations

• Inbound purchase orders and expected receiving timelines

This allows retailers to take action the moment something changes, not days later, reducing stockouts, miscommunication, and decision delays.

2. Intelligent Forecasting

Predicting demand manually through spreadsheets is both time-consuming and highly error-prone. Stock management software uses intelligent forecasting models to predict what customers will buy next.

Forecasting considers:

• Historical sales trends

• Seasonal surges

• Promotions and events

• Store-wise buying patterns

• Product velocity and sell-through

The benefit: You know exactly how much to stock, where to stock it, and when. No more guesswork, overbuying, or last-minute firefighting.

3. Automated Purchase Planning

Instead of waiting for someone to notice “we’re running low,” software automates replenishment based on rules you set.

Automation includes:

• Auto-trigger purchase orders when stock hits safety thresholds

• Auto-suggest reorder quantities based on demand velocity

• Real-time alerts for low stock, fast movers, or out-of-stock risks

• Vendor lead-time calculations to avoid delayed arrivals

This transforms replenishment from a reactive task into a predictive, self-running workflow. Retail teams can finally stop monitoring spreadsheets and focus on strategy.

4. Integrated Reporting & Dashboards

With spreadsheets, every report requires digging through files, merging data, and correcting errors. Software consolidates everything into clean, visual dashboards.

Retailers get instant insights into:

• Stock movement & aging

• Sales vs. inventory performance

• Fulfillment accuracy

• Shrinkage and discrepancies

• Vendor performance

• Category- and store-wise demand trends

Interactive dashboards make it easy to identify what needs attention and make decisions faster, without manual report building.

Final Words

Spreadsheets may feel familiar, but they simply can’t keep up with real-time consumer demand, multi-location operations, and the speed modern retail requires. Stock management software gives retailers what spreadsheets never can: live visibility, accurate forecasting, automated replenishment, and complete control across the supply chain.

Brands that upgrade now reduce costs, prevent stockouts, and create a smoother, smarter retail operation end to end. If you’re still relying on manual tracking, you’re not just losing time; you’re losing revenue, agility, and competitive advantage.

Ready to Move Beyond Spreadsheets?

Supplymint empowers retailers with intelligent demand forecasting, automated replenishment, and real-time inventory visibility, all in one connected platform. Book a demo and see how Supplymint helps future-ready retailers stay in stock, stay efficient, and achieve true supply chain control.

Frequently Asked Questions

1. What are the signs that a retailer has outgrown spreadsheets?

You’ve outgrown spreadsheets if:

• Stock accuracy drops every audit

• Stores keep requesting replenishment late

• Teams rely on WhatsApp/Excel files for updates

• You face frequent stockouts or dead stock

• Forecasting takes too long or depends on guesswork

2. How does stock management software improve demand forecasting?

Unlike spreadsheets, stock management software uses:

• Historical sales trends

• Real-time store performance

• Seasonality and events

• SKU velocity

• Safety stock rules

3. Does switching from spreadsheets to software reduce operational costs?

Yes. Software helps retailers:

• Cut excess inventory

• Prevent emergency procurement

• Reduce manual labor and errors

• Improve warehouse turnaround

• Optimize ordering cycles

These improvements directly reduce operating costs across the supply chain.

4. Can stock management software help manage multiple stores or warehouses?

Absolutely. A stock management tool provides centralized visibility across all locations. You can track stock balances, trigger store transfers, monitor fast/slow-moving SKUs, and forecast store-wise demand, all from a unified dashboard.

5. Is stock management software difficult to implement for growing retailers?

Modern systems like Supplymint are built for fast onboarding. They integrate with POS, ERP, and WMS systems, and your team can operate them with minimal training. The goal is to simplify operations, not add complexity.

6. How does automation help reduce stockouts in retail?

Automation ensures that replenishment happens before stock runs out.

Software can automatically:

• Detect low-stock levels

• Trigger purchase orders

• Suggest store transfers

• Alert buyers about fast-moving SKUs

This proactive approach prevents last-minute shortages.

7. How does a stock management system help improve customer experience?

Customers find what they want, when they want it. Better forecasting and replenishment means fewer stockouts, faster order fulfillment, and consistent product availability, leading to higher satisfaction and repeat purchases.

8. Is stock management software worth the investment for small and mid-size retailers?

Yes. Even smaller retailers face rapid demand shifts, multi-channel operations, and rising logistics costs. Software pays for itself by preventing stockouts, reducing dead stock, and improving planning accuracy.