Procurement organization structure defines how a company’s procurement function is organized, including team roles, reporting lines, and decision-making authority. For growing businesses, a well-designed procurement organization structure is critical to controlling costs, improving purchasing speed, maintaining compliance, and increasing operational visibility.

An inefficient structure often leads to slow approvals, inconsistent buying, poor supplier coordination, and limited spend transparency. In contrast, a clear procurement structure helps teams standardize processes, reduce risk, and scale procurement operations effectively.

What Is a Procurement Team?

A procurement team is the group responsible for managing how an organization sources, purchases, and manages goods and services from external suppliers. Beyond buying products, the procurement team ensures that purchasing decisions align with cost targets, quality standards, timelines, and internal policies.

Key highlights:

• The procurement team manages supplier selection, purchasing workflows, and vendor relationships, not just ordering materials.

• It plays a critical role in spend control, compliance, and risk management across the organization.

• A well-structured procurement team connects finance discipline with operational and supply chain execution.

Procurement Department Organizational Structure Explained

The procurement department organizational structure defines where procurement sits within the overall business and how purchasing authority is distributed. Procurement typically reports into finance, operations, or the supply chain, depending on whether the organization prioritizes cost control, speed of execution, or supply coordination.

When procurement is clearly positioned with defined reporting lines, teams operate with better accountability, faster approvals, and stronger spend visibility. Poorly structured procurement departments, on the other hand, often face delays, duplicated purchasing, and unclear ownership of supplier decisions.

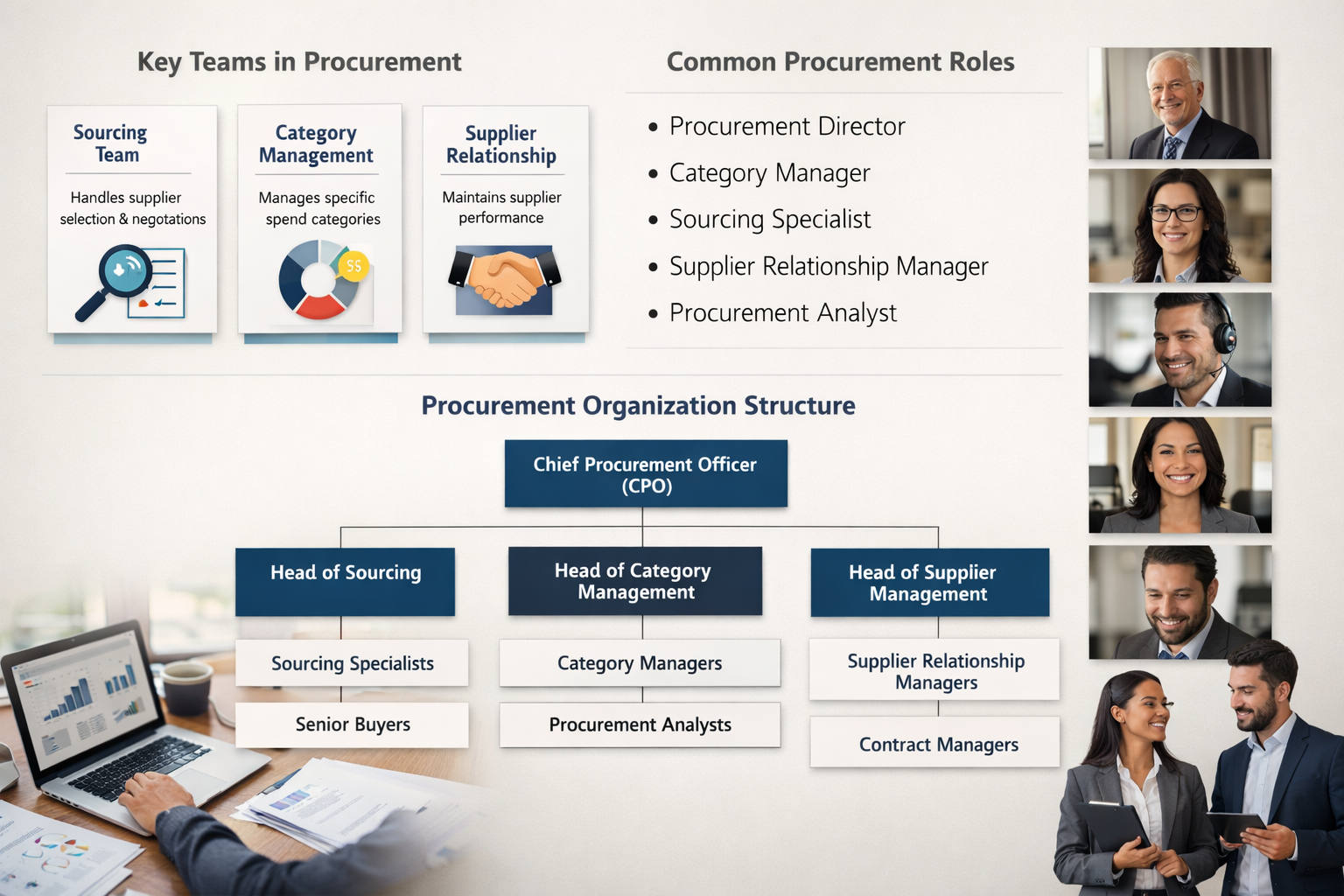

Procurement Organization Structure: Key Roles and Responsibilities

A well-defined procurement organization structure clearly outlines who owns strategy, execution, and supplier relationships. This role clarity is essential for efficient purchasing and spend control.

Key roles in a typical procurement team include:

• Head of Procurement / CPO: Defines procurement strategy, policies, and governance aligned with business goals.

• Procurement or Category Managers: Manage specific spend categories, supplier negotiations, and contract performance.

• Buyers or Purchasing Executives: Execute day-to-day purchasing activities, process requisitions, and coordinate with suppliers.

• Supplier or Compliance Roles (where applicable): Oversee vendor performance, risk, and adherence to internal policies.

Procurement Organization Chart Explained

A procurement organization chart visually represents how the procurement function is structured, showing reporting lines, role hierarchy, and decision-making authority. It helps teams understand who owns strategy, who executes purchasing, and how approvals flow within the procurement organization structure.

A well-designed procurement org chart clarifies responsibility and reduces confusion in purchasing workflows. However, when org charts are overly rigid or layered with too many approvals, they can slow down procurement and create operational bottlenecks.

What a Procurement Organization Chart Shows

| Element | What It Represents | Why It Matters |

| Role hierarchy | Reporting structure from leadership to buyers | Clarifies ownership and accountability |

| Approval flow | How purchase requests move across roles | Prevents delays and approval confusion |

| Decision authority | Who can approve spend and contracts | Controls risk and unauthorized purchases |

| Team alignment | How procurement connects with finance and operations | Improves coordination and visibility |

Centralized vs Decentralized Procurement Organization Structure

The way purchasing authority is distributed plays a major role in how effective a procurement organization structure is. Companies typically follow a centralized, decentralized, or hybrid procurement model, depending on their size, complexity, and control requirements.

1. Centralized Procurement Organization Structure

In a centralized procurement organization structure, purchasing authority is consolidated under a single procurement team or leadership group. All sourcing decisions, supplier negotiations, and approvals follow standardized processes.

This model offers stronger cost control through bulk purchasing, supplier consolidation, and consistent compliance. It is commonly used by organizations with high spend volumes, multiple locations, or strict governance requirements, such as manufacturing, retail chains, and regulated industries.

2. Decentralized Procurement Structure

A decentralized procurement structure allows individual departments or business units to manage their own purchasing decisions. Teams have greater autonomy to source vendors and approve purchases based on local or functional needs.

While this approach improves speed and flexibility, it often increases the risk of inconsistent pricing, duplicated suppliers, and reduced spend visibility. Without strong controls, decentralized procurement can lead to higher overall costs and policy gaps.

3. Hybrid Procurement Structure (Modern Approach)

A hybrid procurement structure combines centralized strategic control with decentralized execution. Core activities such as supplier onboarding, contracts, and pricing are managed centrally, while departments retain flexibility for operational purchasing.

How Organizational Buyers Are Divided Into Three Markets

Organizational buyers are divided into three markets based on the type of customers they serve and how purchasing decisions are made. Understanding these markets helps businesses design a procurement organization structure that aligns with buying complexity, compliance needs, and scale.

• Industrial market buyers include manufacturers, producers, and service providers that purchase raw materials, components, and services for production or operations. Their procurement structures are typically process-driven, with strong emphasis on supplier reliability, cost efficiency, and long-term contracts.

• Reseller market buyers purchase finished goods for resale, such as wholesalers, distributors, and retailers. Procurement teams in this market focus on pricing, supplier diversity, lead times, and demand-driven purchasing, often requiring close coordination with inventory and sales teams.

• Government and institutional market buyers include public sector organizations, hospitals, universities, and non-profits. Procurement structures in this market are highly regulated, with strict approval processes, transparency requirements, and compliance-driven purchasing.

How to Design the Right Procurement Organization Structure

Designing the right procurement organization structure requires aligning procurement roles, authority, and workflows with how the business actually operates. There is no universal model that works for every organization, which is why procurement organization design must be context-driven.

Key Factors That Shape Procurement Organizational Design

| Design Factor | What to Consider | Impact on Procurement Structure |

| Business size and complexity | Number of locations, SKUs, and spend volume | Determines team size, hierarchy, and level of centralization |

| Supplier base and geography | Local vs global suppliers, vendor count | Influences coordination needs and sourcing strategy |

| Approval layers and compliance | Regulatory requirements and internal controls | Defines approval workflows and governance depth |

Why One-Size-Fits-All Procurement Structures Fail

Procurement organizational design that is copied from other companies often fails to scale. Structures that are too rigid slow decision-making, while overly flexible models reduce cost control and visibility. The most effective procurement organization structures evolve with business growth, balancing control, speed, and accountability through the right mix of roles, processes, and technology.

The Role of Technology in Modern Procurement Organization Structure

Technology plays a critical role in shaping a modern procurement organization structure by reducing manual effort and simplifying coordination across teams. Digital procurement systems allow organizations to operate with leaner procurement teams while maintaining control and visibility.

With centralized digital platforms, procurement leaders gain real-time visibility into spend, suppliers, and approvals without forcing all decisions through a single team. This enables hybrid procurement models where governance is centralized, but execution remains flexible across departments and locations.

Automation also streamlines approval workflows and supplier communication. Faster approvals, shared data, and standardized processes reduce bottlenecks, improve coordination between procurement, finance, and operations, and help procurement teams focus on strategic activities instead of administrative tasks. Modern procurement technology supports scalable organization structures that grow with the business rather than slowing it down.

Common Procurement Organization Structure Mistakes to Avoid

• Too many approval layers: Excessive approval steps slow down purchasing, delay operations, and turn procurement into a bottleneck instead of a support function.

• Unclear ownership between teams: When roles overlap between procurement, finance, and operations, accountability breaks down and decisions take longer.

• Manual processes slowing procurement: Heavy reliance on emails, spreadsheets, and disconnected tools reduces visibility and increases cycle time.

• Procurement operating in isolation: Lack of alignment with inventory, finance, and supply chain leads to inefficient purchasing and poor business outcomes.

Final Takeaway

A scalable procurement organization structure must evolve as the business grows. The right structure balances control with speed, ensuring cost visibility, compliance, and efficient purchasing without slowing operations.

Technology makes this balance possible. Solutions like Supplymint’s DigiProc enable centralized visibility, automated approvals, and smoother coordination across procurement, finance, and operations, supporting centralized, decentralized, and hybrid procurement models.

Looking to streamline your procurement operations? Explore how Supplymint DigiProc helps build efficient, scalable procurement structures.

Frequently Asked Questions

1. What is the ideal size of a procurement team?

There is no fixed size for a procurement team. The ideal team size depends on spend volume, number of suppliers, purchasing frequency, and business complexity. Many growing organizations use lean teams supported by digital procurement tools to scale without adding headcount.

2. Who should procurement report to in an organization?

Procurement commonly reports to finance, operations, or supply chain leadership. The reporting line depends on whether the business prioritizes cost control, operational speed, or supply coordination. There is no single best reporting model for all organizations.

3. How does procurement structure change as a company scales?

As companies grow, procurement structures typically shift from informal or decentralized models to more structured or hybrid approaches. This change helps improve spend visibility, supplier governance, and approval efficiency while supporting higher purchasing volumes.

4. Can small businesses benefit from a defined procurement organization structure?

Yes. Even small businesses benefit from a defined procurement structure, as it helps control spending, standardize purchasing decisions, and prevent process gaps as the business expands.

5. How do digital tools support procurement organization structure?

Digital procurement tools support procurement structures by automating approvals, improving spend visibility, and enabling collaboration across teams. This allows organizations to maintain governance without adding unnecessary complexity or slowing down purchasing.

6. What is the difference between procurement structure and procurement process?

Procurement structure defines who is responsible for purchasing decisions and approvals, while procurement process defines how those decisions are executed. Both must work together for procurement to operate efficiently.