Introduction

Supply chain work used to be slow, tiring, and full of long hours doing the same tasks again and again. Workers would write down numbers, move papers, update files, check stock, and track products by hand. All of this took time and often caused mistakes. That is why supply chain automation has become so important in business. When companies choose to automate supply chain processes, they can reduce manual work, save money, and keep customers happy. This change is happening in companies of all sizes across the world.

In this blog, we will talk about what supply chain automation is, how it works, and why it is helping businesses cut down on manual work. We will explain why things like automation in inventory tracking and manual workflow reduction in logistics are no longer ideas for the future, but real tools that companies use today. This content also explains how supply chain process improvement makes every part of the system easier, faster, and smarter for workers and managers.

What Is Supply Chain Automation?

When we talk about supply chain automation, we mean using machines and smart software to do the jobs humans once did by hand. For example, instead of an employee writing down how many items are left in storage, a machine or software can do it for them. This saves time and reduces errors. Automation covers many parts of the supply chain such as:

• Tracking inventory automatically

• Updating records without human entry

• Sending alerts when items run low

• Scheduling deliveries on time

Every task that used to need manual effort can be handled by automated systems. This is why companies choose to automate supply chain processes and keep things moving smoothly.

Easy Example of Supply Chain Automation

Think about a store selling toy cars. In the old way, a worker must count every toy and update a list by hand. If they forget, the list becomes wrong. With automation, a sensor or software counts items for you and keeps the numbers correct. This helps the store order more toys before they sell out.

This change from writing by hand to using automatic counting is what supply chain automation is all about.

Why Is Supply Chain Automation Important?

Supply chain work touches almost every part of a business — from ordering products, storing them, moving them, and delivering them. Manual tasks can hold everything back. Automation helps in many ways.

Here are the main reasons why businesses are adopting automation:

1. Fewer Errors and Mistakes

When humans enter data, mistakes happen. Typing errors, lost papers, or wrong updates can lead to big problems later. Automated systems check everything and update records correctly every time.

Explanation:

Imagine a worker typing the number of products left in stock. If they type a wrong number, the store might think they have more than they actually do. That mistake can cause delays or unhappy customers. When software does the counting and updating, the numbers are always correct.

2. Saves Time and Energy

Routine tasks like checking stock, sending emails, or creating reports take up a lot of time. Machines and software do these jobs quickly. This gives workers more time to do important jobs that need thinking and planning.

Explanation:

Time saved on simple tasks means staff can focus on new ideas, improve customer service, and manage problems before they grow.

3. Better Inventory Management

One big part of the supply chain is watching how much stock a company has. With automation in inventory tracking, systems update stock levels in real time. This means companies know what they have right now, not what someone wrote down hours ago.

Explanation:

If a store runs out of stock, customers may go elsewhere. If it keeps too much stock, money sits unused. Automated tracking helps balance these problems.

4. Faster Deliveries and Workflows

Workflows are the steps that help products move from one stage to the next. When these steps happen by hand, delays are frequent. Automation speeds up workflows. For example, automated systems can schedule shipments instantly without waiting for people to type orders.

Explanation:

Faster workflows make customers happy because they receive orders on time. It also brings trust and better service ratings.

5. Reduced Costs for Businesses

Doing work by hand costs money — pay for staff, costs of mistakes, and delay fees. When automation reduces manual hours, companies spend less on labor and save on expensive mistakes.

Explanation:

Money saved on simple tasks can be used to grow the business, hire skilled workers, or offer better services.

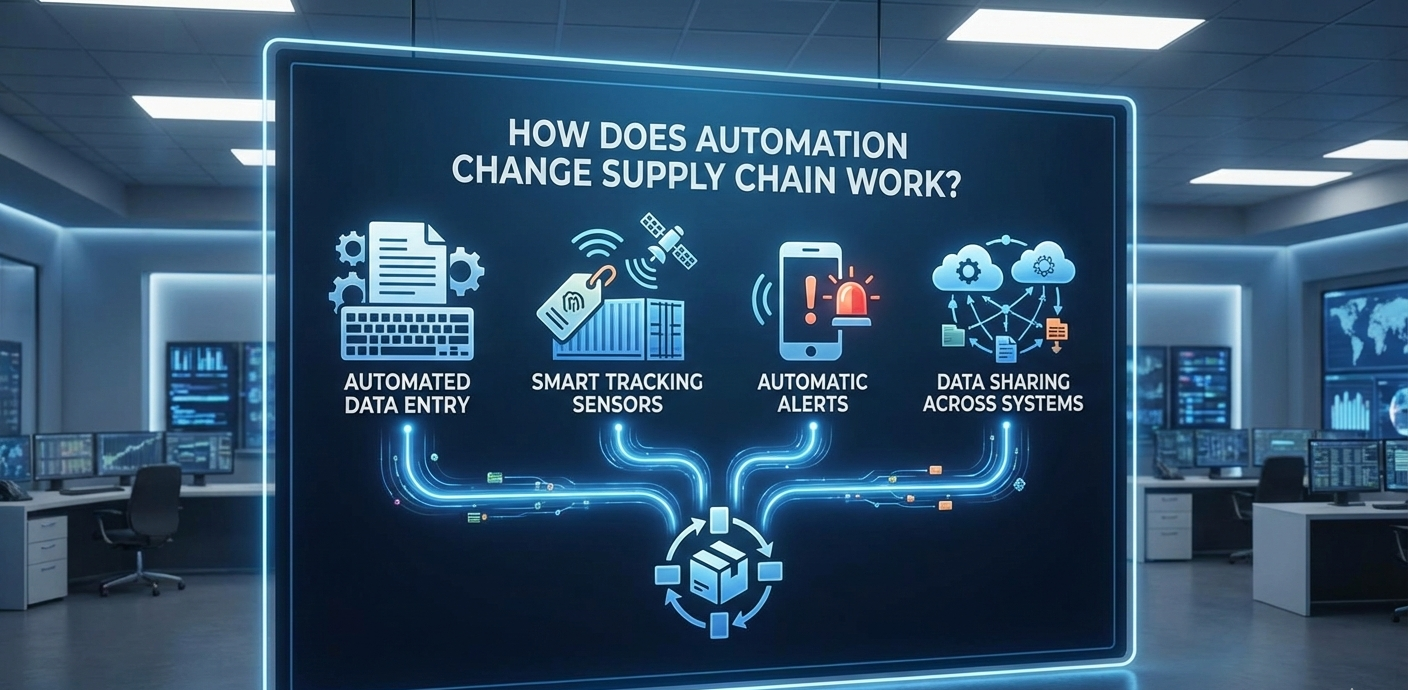

How Does Automation Change Supply Chain Work?

Automation is not just one thing. It is a mix of smart tools that work together to make the supply chain better.

Here is how automation changes key tasks:

Automated Data Entry

Old way: Workers type data into a system.

New way: Machines capture data and send it to the system automatically.

Explanation:

This stops the problem of wrong numbers and saves hours of work every day.

Smart Tracking Sensors

Old way: Workers count products by hand.

New way: Sensors and software watch inventory and report numbers in real time.

Explanation:

This helps companies use automation in inventory tracking so they know what they have anytime.

Automatic Alerts

Old way: No checks until a worker finds a problem.

New way: Systems send alerts when stock is low or late shipments arrive.

Explanation:

Alerts help teams act fast before problems become costly.

Data Sharing Across Systems

Old way: Separate systems don’t talk to each other.

New way: Automated platforms share data across departments.

Explanation:

Everyone in the company sees the same updated information, reducing confusion and delays.

These changes all help companies reduce the time and effort spent on manual work.

Real Life Examples of Supply Chain Automation

Here are a few clear examples where automation makes big differences:

Automated Inventory Scanning

Some companies use scanners and systems that count products automatically. This replaces manual counts and cuts errors.

Real-Time Tracking of Shipments

Instead of calling warehouses or truck drivers to ask where a product is, automated tracking systems show live locations on a screen. This helps logistics teams react fast if there is a delay.

Robots in Warehouses

Some warehouses use robots to move boxes, pick items, and load trucks. Humans tell the robots what to do, and the robots do the heavy work more quickly.

Predictive Tools

Advanced software can look at old sales numbers and forecast what customers might order next. This helps companies plan stock and avoid shortages.

What Is Manual Workflow Reduction in Logistics?

Logistics means moving products from place to place. Before automation, this meant lots of calling, emails, posting messages, and copying data. Manual workflow reduction in logistics means using machines and smart software to do these tasks for us.

Here is a very simple comparison:

| Manual Workflow | Automated Workflow |

| A person checks stock by hand | Sensors update stock automatically |

| Worker calls warehouse for status | System shows real-time status |

| Employee copies numbers to software | System sends numbers instantly |

This type of manual workflow reduction in logistics removes repeated tasks and helps teams focus on planning, fast solutions, and better customer responses.

How Supply Chain Process Improvement Happens

Process improvement means making work easier, faster, and more accurate. When companies start using automation, they begin to solve problems that cost time and money.

The steps of improvement include:

1. Mapping Workflows:

• First, companies list all steps in the supply chain.

• They find tasks that take the longest.

2. Finding Manual Tasks to Replace:

• Tasks like typing data or calling suppliers are marked as manual work.

• These are good candidates to automate.

3. Choosing Automation Tools:

• Companies pick software or machines that can handle the jobs.

• Systems like tracking tools or automatic alerts are installed.

4. Testing and Learning:

• Tools are tested in a small area.

• Once they work well, they are rolled out to the whole supply chain.

5. Review and Improve:

• Companies watch how automation changes operations.

• They update or fine-tune tools to keep improving.

This step-by-step approach means companies don’t lose control. They improve slowly but steadily.

Benefits of Supply Chain Automation for Different Areas

Supply chain automation touches many parts of a business. Here is what changes in each part:

Inventory Management

• Tools track stock levels in real time

• Alerts when stock runs low

• No need for manual counts

• Better balance of stock and sales

Shipping and Delivery

• Automated routing picks fastest routes

• Shipping updates go to customers without phone calls

• Fewer delays and errors

Order Processing

• Systems check orders and send them to warehouses without human work

• Packing slips and labels are auto-generated

• No mixed-up orders

Reporting and Planning

• Data flows into dashboards

• Teams see trends and make faster decisions

• Reports are ready without manual Excel sheets

This list shows how every area works better once manual tasks are switched to automation.

How Businesses Start with Task Automation

For many companies, the idea of full automation seems big and hard. But businesses don’t do it all at once. They start small:

1. Automate a single task – like updated inventory levels

2. Connect it to other systems – so data flows across departments

3. Add alerts and notifications – to catch problems early

4. Use dashboards – to see everything live

Once these steps work well, companies add more automation tools and expand across the whole supply chain.

Future of Supply Chain Automation

Experts say automation will keep growing in supply chains. This means:

• More smart tools that use data

• Better demand predicting systems

• More robots in warehouses

• Real-time updates in all areas

The future belongs to companies that understand automation, help workers adapt, and use technology to improve every day.

Final Thoughts

Supply chain automation has changed how work gets done in businesses today. By using tools that handle boring, repetitive tasks, companies improve their systems, reduce errors, and save time and money. From supply chain process improvement to automation in inventory tracking and manual workflow reduction in logistics, automation makes every step smarter and more dependable. Companies that choose to automate supply chain processes are better prepared for the future and can keep customers happy with faster deliveries and fewer mistakes.

If your business wants to reduce manual tasks and improve its entire supply chain, tools and solutions from Supplymint can help you get started and grow with confidence.

FAQs About Supply Chain Automation

1. What does “supply chain automation” mean?

Supply chain automation means using machines and software to do tasks that used to be done by hand. This reduces mistakes, saves time, and keeps work flowing without delays.

2. Why is automation important for inventory tracking?

Automation in inventory tracking means systems update the number of items automatically. This helps businesses know what they have right now and avoid running out or having too much stock.

3. How does automation reduce manual work in logistics?

When systems send updates, schedule shipments, and track products, workers no longer need to make phone calls or type information by hand. This is manual workflow reduction in logistics.

4. Will automation replace all workers?

No. Automation does repetitive jobs, but workers are needed for planning, managing, and solving important problems. It helps humans do better work, not replace them.

5. Can small businesses use automation too?

Yes. Many small businesses can start with simple tools like automatic inventory alerts or order processing software. This helps them grow without heavy manual tasks.